PosiBlog

The Advantages of Stainless Steel Connectors

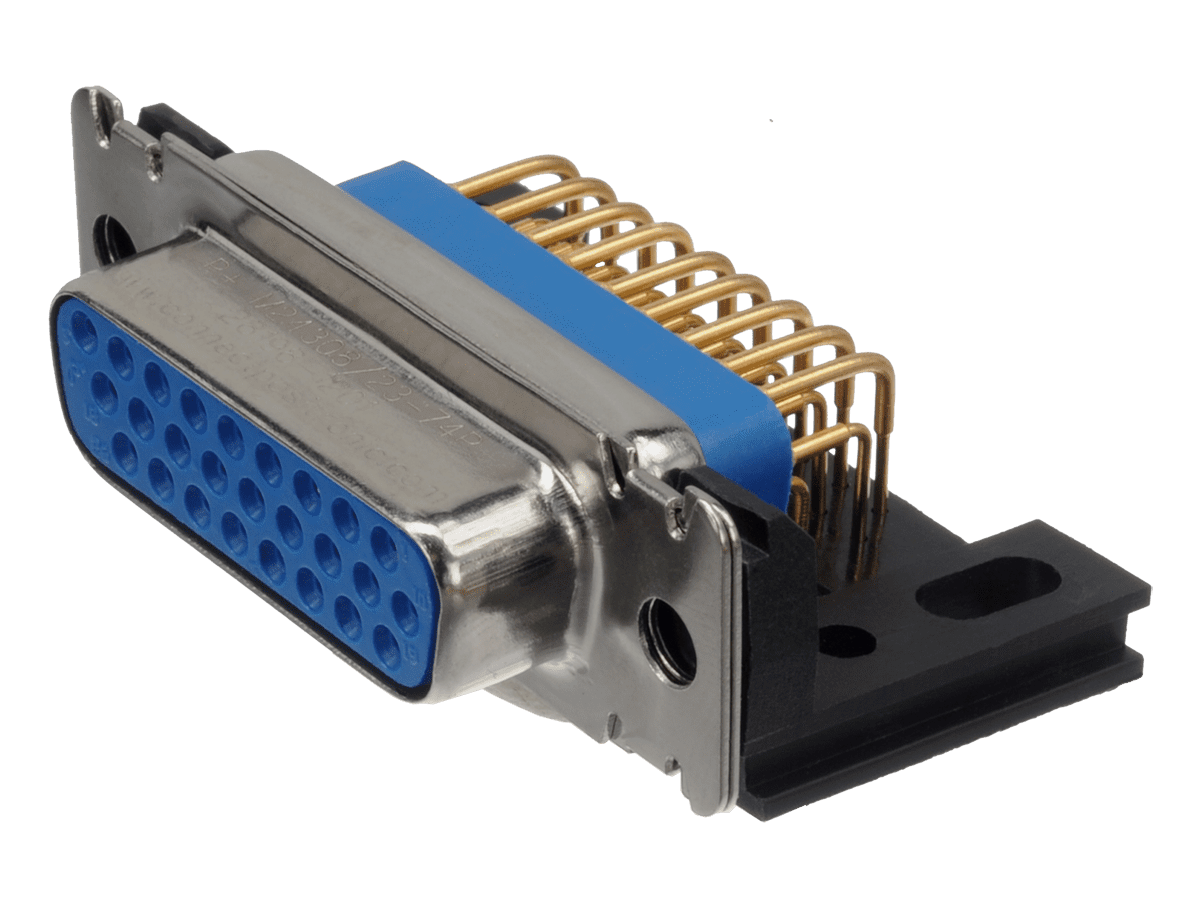

Anyone who works with electronics is familiar with the trapezoidal shape of the D-Sub connector. However, have you ever wondered why Positronic makes them with stainless steel? Read on to learn about the advantages of stainless steel connectors over other materials, and why they’re used in military standards.

The Advantages of Stainless Steel Connectors

Size Matters, But Material Matters More

If you’ve worked with electronic connectors before, you know that size matters. Namely, the smaller, the better. As machines evolved throughout the 1960s, the need for slimmer and more compact connectors emerged. Enter the D-Sub connector. The streamlined shape of the D-Sub connector opened up a world of possibilities for engineers.

Once the D-Sub connector became an industry standard, the military applications were obvious. However, in order to meet military specifications, machine components have to be able to stand up to the harsh conditions of combat.

D-Sub connector shells are typically made with steel sheets. Steel is a strong material, but it is vulnerable to moisture and can rust. Plating the steel with a protective coating works as a temporary solution, but plating materials are vulnerable to failure and can also be hazardous to the environment. An industry appetite arose for shell material options that could survive combat scenarios as well as the rigors of temperature and humidity extremes.

The Positronic M-24308 D-Sub Connector

To solve this problem, Positronic turned to stainless steel. Stainless steel doesn’t rust, can withstand high temperatures safely, and is a generally strong metal alloy. It also conducts electricity, making it an ideal metal to use for a D-Sub connector. Using stainless steel allowed Positronic to develop the M-24308 D-Sub connector within the military standards required for construction and materials. That’s why so many pieces of military technology use Positronic parts. Today, Positronic offers over 600 Qualified Products Listed (QPL) stainless steel D-Sub conductors. That’s a wider range than anyone else in the industry!

However, the benefits of stainless steel connectors are not only available to military customers. Positronic has the in-house expertise needed to craft a wide array of D-Sub connectors out of stainless steel for all industries and all applications. We also have a vertically integrated manufacturing plant right here in the United States, so you can proudly tell customers your machine parts were made in the USA.

We make high-performing connectors affordable and accessible to everyone. Why settle for any other connector when military-grade efficiency and performance are available at Positronic?

_____

While the D-Sub connector revolutionized electronics, it took stainless steel to bring the connector to its full potential. Don’t waste your time and money on connectors made from lesser materials. Purchase your stainless steel connectors from Positronic, and see the difference for yourself.

At Positronic, we believe in crafting versatile, high-quality connectors. Our design and manufacturing processes meet and often exceed our customers’ needs for quality and reliability. And to suit the needs of our varied customers, we have a plethora of options available. If you would like to request product recommendations, locate a sales agent, ask a technical question, or simply request a quote, please contact Positronic today.

Latest Posts

- Milexia and Neumueller Named as Exclusive Value-Add Distributor Partners for UVAC Hermetic Feedthrough Flange System March 26, 2025

- Powering the Future of eVTOL Aircraft Travel January 24, 2025

- MACH-D Connectors: Highly Reliable & Customizable August 29, 2024

- Combo-D Connectors from Positronic: Compact Power and Precision May 1, 2024

- A Series Backshell Product Derivative: Introducing Precision Machined Banded Backshells March 12, 2024