PosiBlog

Not All D-Subs Are Created Equal

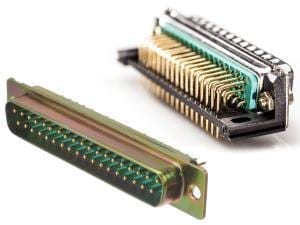

The D-sub is one of the most popular electronic connectors in the world, with many types, sizes, and applications. It’s a big category with a dizzying number of choices – not all of which are created equal. That’s especially true when it comes to density and durability.

“D-sub” is short for D-subminiature, with the “D” referring to their characteristic D-shaped housing. When first introduced back in 1952, they were one of the smallest connectors in the computing world – thus earning the name, “miniature.” Today? Not so much. Here on the far side of the micro revolution, they’re actually one of the larger ones.  But their utility persists, and has even expanded. To understand why, one only needs to look at the MIL-DTL-24308 versions or as they are affectionately called, “M24308” D-subs.

But their utility persists, and has even expanded. To understand why, one only needs to look at the MIL-DTL-24308 versions or as they are affectionately called, “M24308” D-subs.

Positronic produces a wide range of D-sub connectors. The M24308 is one of the most robust, built to the very specific requirements of the U.S. military. Its design, for instance, accounts for volatile environmental factors – protecting the connection against extreme conditions and vibration.

MIL-DTL-24308 connectors continue to be an ideal choice for important – and difficult – tasks in the military and aerospace sectors. They’re small enough to fit into tight spaces, reliable enough to live a long life and properly shaped for low-profile LRUs. When space and weight are critical and the user needs to accommodate many circuits in proportion to their size, the M24308 connector has been a consistent go-to solution.

The size and efficiency of the M24308 suits it well for high-density electronics found in aircraft, missiles, and related ground support systems. Engineers specify them for military equipment, computer peripherals, modems, information and communication systems, industrial instruments, ground support devices, and spaceflight equipment.

The M24308 itself comes in many different styles and formats with a variety of options for class (general, space, and non-magnetic), contact termination (crimp, solder cup, and straight or right-angle PCB mount), and type (standard density, high density, and combo-D). They have a wide temperature range and are designed to operate between -55°C and +125°C.

While most military-standard connectors have a circular design, the M24308 D-sub is low profile, taking up less vertical real estate on a panel. And with metal shells, there is additional protection and strength. Positronic is one of the main providers of connectors with stainless steel shells, which meets current green standards (stainless steel isn’t an environmental hazard like cadmium and some other electroplatings).

All D-subs may not be equal, but the M24308 is a name that continues to earn the trust of the industry. And with newly introduced standards, mil-spec connectors like the M24308 are only getting better.

Latest Posts

- MACH-D Connectors: Highly Reliable & Customizable August 29, 2024

- Combo-D Connectors from Positronic: Compact Power and Precision May 1, 2024

- A Series Backshell Product Derivative: Introducing Precision Machined Banded Backshells March 12, 2024

- Exploring the E-Mobility Market with Positronic Connectors December 1, 2023

- Positronic Announces EL Series Aluminum Backshells August 7, 2023